How does ultrasonic welding work?

First, an ultrasonic generator produces an electric current with an approximate tension of 1000V, a frequency of 20, 30, 35 or 40 kHz, and a 1A intensity.

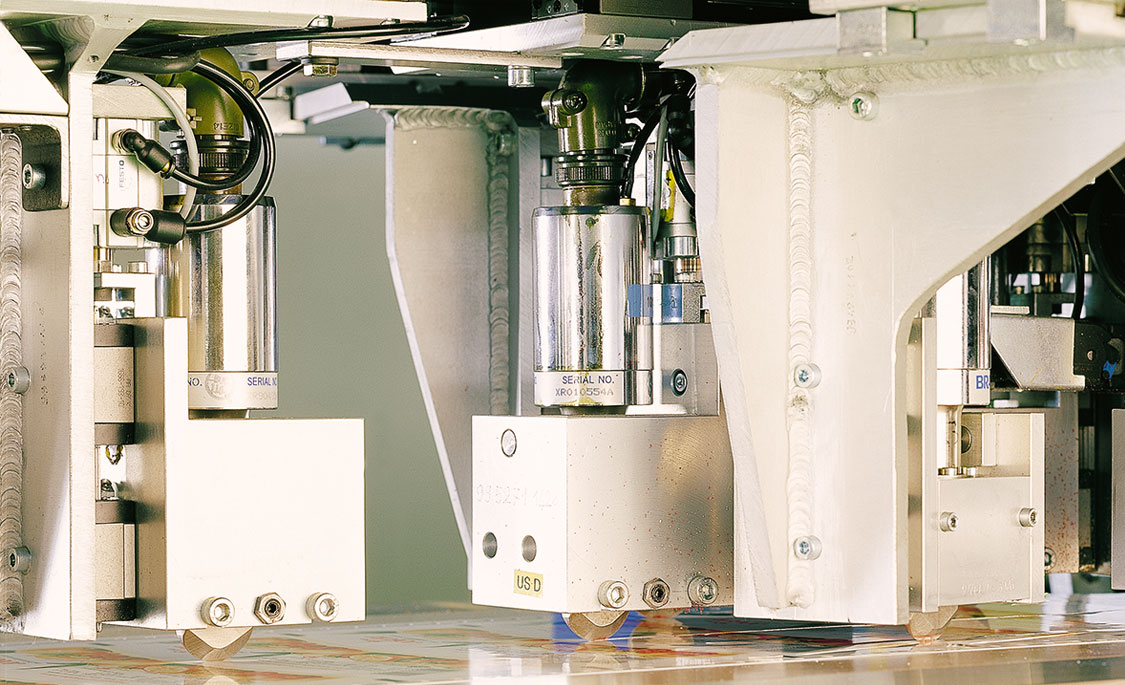

Then, the generator delivers the electric current through an ultrasonic cable until a ceramic made converter. The ceramics vibrate at the chosen frequency (20, 30, 35 or 40 kHz) and generate a few microns amplitude.

The converter then generates positive and negative vibrations and transforms the electric current into mechanic energy.

Afterwards, a sonotrode in steel or titanium which is connected to the mechanic association vibrates at the imposed amplitude. For instance:

– For 20 kHz, the sonotrode generates a 20 to 25 microns amplitude

– For 30 kHz, a 15 to 16 microns amplitude

– For 40 kHz, an 8 microns amplitude

The active face of the sonotrode realizes a hammering while an anvil faces it (or a drum for rotary ultrasonic). The product then passes between the anvil and the active face of the sonotrode, rises in temperature and melts, what generates cut or welding according to the machine.

Are there multiple types of ultrasonic welding?

At Cera Engineering, ultrasonic welding can be two types:

– Static welding (intermittence welding)

– Continuous welding (rotary welding)

You want to learn more about this technology? Please check out our new website: Machines to weld and/or cut by sonics