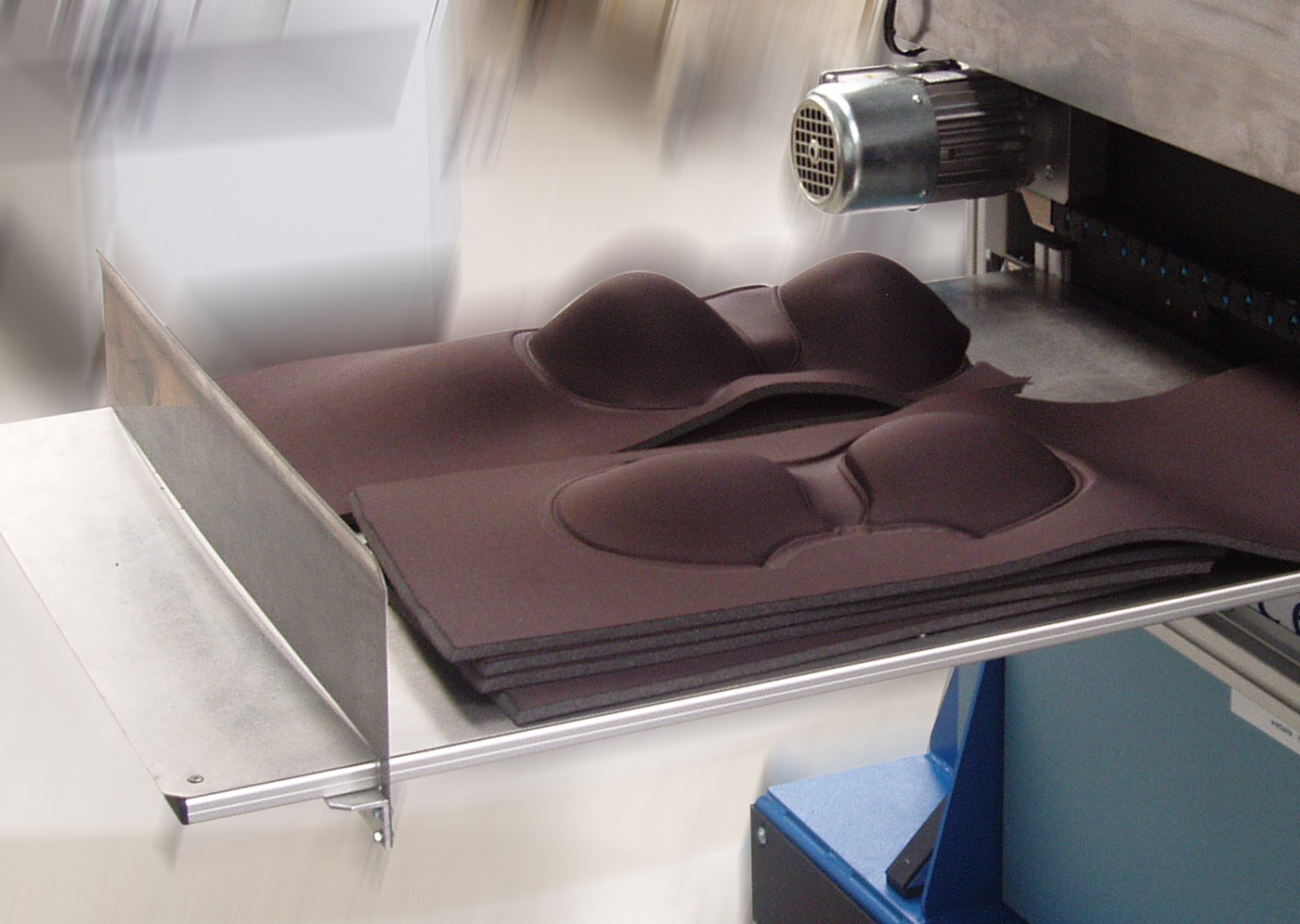

Process

Automatic operations:

• Unwinding of the foam

• Thermo-moulding of the foam by compression

• Separating cut of the pairs

• Storage

Foam and cup features

• Effective working zone per pair :

– Maximum in width: 300 mm

– Maximum in length: 400 mm

• Optimization of the consumption of the foam

• Any shape of cups

Technical features

• Output: up to 50 pairs an hour depending on the foam and coating

• Heating temperature: up to 300° C

• Heating precision: +/- 1°C

• Defect analysis of the moulding pressure

• Pneumatic: 6 bar

• Electrical tension: 380 V threephase + neutral, 32 A

• Machine dimensions:

– Dimensions (in m.): 1.80 x 1.10 x 2.60 (h x w x l)

– Weight: 1035 kg

Why Cera Engineering?

Because we combine years of experienced know-how in ultrasonic welding, with a technical expertise as a manufacturer of production machines. Industrial equipment at competitive prices. A wide range of cutting and welding tooling.

Other machines for the lingerie industry

Cera Engineering manufactures a range of machines for the production of lingerie pieces such as bra straps, bra cups and hook-and-eye.

CERA UltraStrap model – Machine for the production of bra straps (threading of the slide and ring)

CERA UltraStrap_R – To assemble complete straps in automatic with a strap collector at the exit of the machine (Slide + Ring).

CERA 520 model – Machine for the production of bra straps (threading of the ring)

CERA 300 model – Automatic machine to cut hook-and-eye strap